Hot Rolled Plates

Hot rolled steel sheets and plates are produced by rolling steel at elevated temperatures, above its recrystallization point, allowing the material to be shaped and formed with ease while maintaining structural strength and ductility. This process provides excellent workability for cutting, bending, and welding, making hot rolled sheets and plates ideal for applications requiring large dimensions and heavy-duty performance. The controlled high-temperature rolling ensures consistent thickness, toughness, and mechanical reliability for demanding industrial projects.

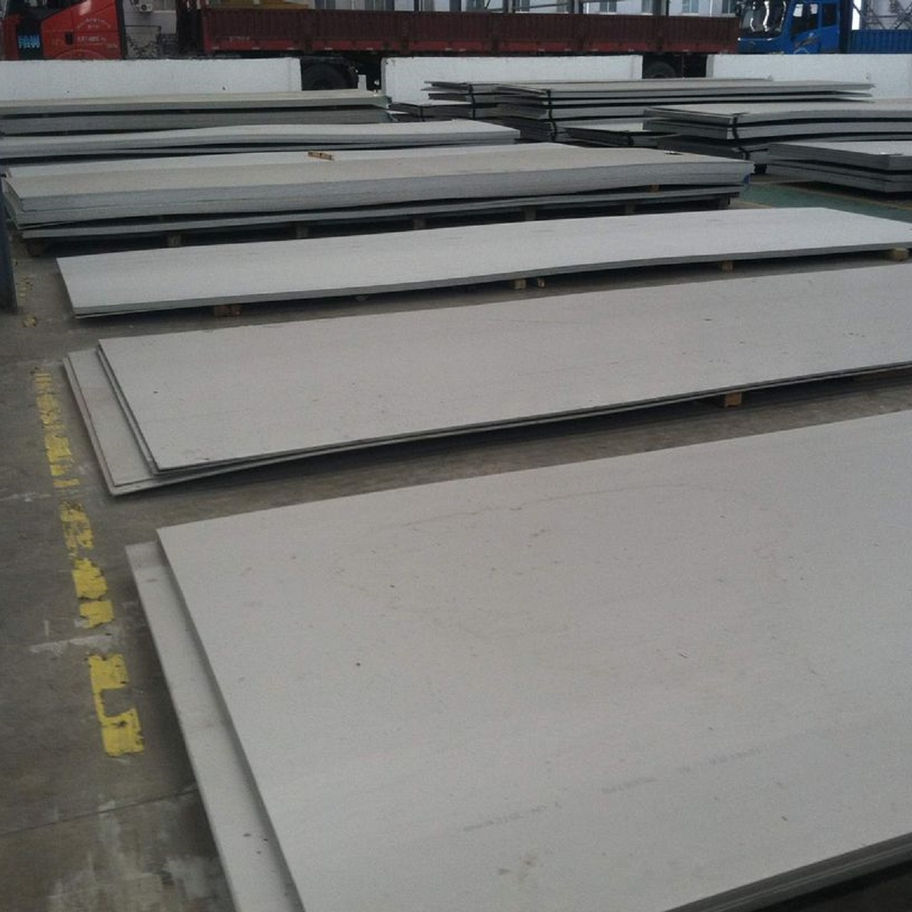

The surface of hot rolled steel sheets and plates typically exhibits a scaled finish, which can be further treated through pickling, coating, or painting to enhance aesthetics and corrosion resistance. Despite the rougher appearance compared to cold rolled steel, hot rolled plates deliver superior toughness and flexibility, particularly in applications where precise surface finish is not critical. Proper storage and handling are recommended to prevent surface rust and preserve the material’s functional integrity.

Applications and Industries: Hot rolled steel sheets and plates are widely used in construction for structural components, bridge building, shipbuilding, and large-scale infrastructure projects. They are also employed in heavy machinery manufacturing, automotive frames, pressure vessels, pipelines, and industrial equipment fabrication. Industries such as energy, transportation, and engineering rely on hot rolled sheets and plates for their robustness, versatility, and suitability for large-scale structural and fabrication applications.